How Ebay Samurai Swords get Made in China - An Inside Look at Sword Making Part Two

Ebay sword sellers often, okay always, claim they have a forge and make the swords they sell themselves. Actually, in 100% of the cases, this is untrue. Yep, they are all lying, and not one of them owns a forge. So where do the mass quantities of swords they sell come from? In some cases, they come from overflow from large factories. Ronin, for example, orders 500+ soshu kitae laminated katana every year. Because of the high failure rate, three blades are forged for every one that we order. The rejected blades are not melted down, or destroyed, but sold to local dealers on the cheap. In most cases, the ebay dealers stock comes from one place. I call it Hammer Town.

So where are all the Master Smiths? You won't find a single master working here. While all of them are skilled, none of the has taken the test to actually become a master. Master smiths in China are broken up into three categories.

Rank One - City level master

Rank two - Provence level master

Rank three - Country level master. Also considered a National Treasure Smith.

When I took the pictures, it was lunch time, and the smiths working this forge were having their meal and playing cards. These are the guys, with a few exceptions, who are banging out 100% of the "hand forged" swords you buy on ebay. The are capable of producing over 100 swords per day. These are not the same people making swords that come from metal extraction. Metal extraction comes from taking a blank and grinding out the sword. The lower end blades are machine made, which means they are stamped out. The next tear up are the half machine, and half hand, which are stamped by a machine, and then hand ground.

The guys working this power hammer factory are pretty skilled at what they do, but they are not making blades on par with what actual ranked smiths crank out. Their skills are more in line with getting bars of steel pounded into huge stacks of swords.

Chinese dealers are known for offering any steel a buyer wants. Sadly, buyers are not getting what they paid for. 1045 steel is the most common steel used, as it's cheap, and can be deferentially hardened. The guys pounding out these blades have absolutely no idea what so ever what kind of steel is being used.

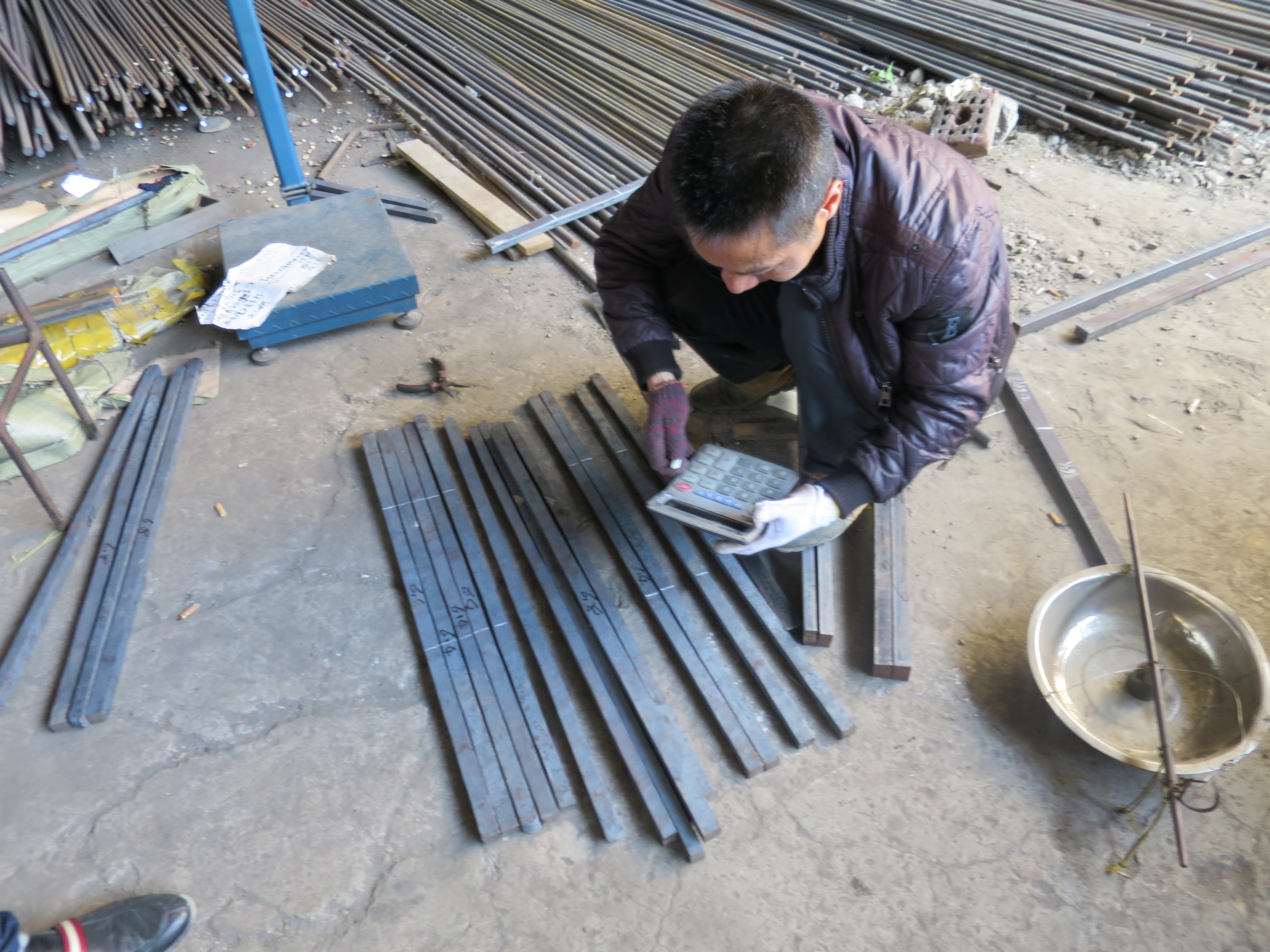

Here's a good look at the steel stocks that are being used at this forge.

To wrap this one up, this where your "hand forged" swords on ebay come from. Right here. Keep in mind this is just the blade making, and not polishing. There are several more steps the sword goes through before it's completed. I'll show those pictures as well.

Recent Posts

-

Want to be a Ninja? They are hiring in Japan.

Have you always dreamed of being a ninja? Did people crush your dreams by telling you Hollywood made …Jul 25th 2018 -

HBO Needs A Samurai Epic

HBO was recently acquired by AT&T in a blockbuster $85 billion deal. John Stankey is now h …Jul 21st 2018 -

Samurai Fantasy Movie Blade of the Immortal on Hulu

Like katana? Like Samurai? Like a body count right out of an 80's Stallone or Schwarzenegger film? T …Jul 12th 2018